Half Stainless Steel Vibration Resistant Pressure Gauge

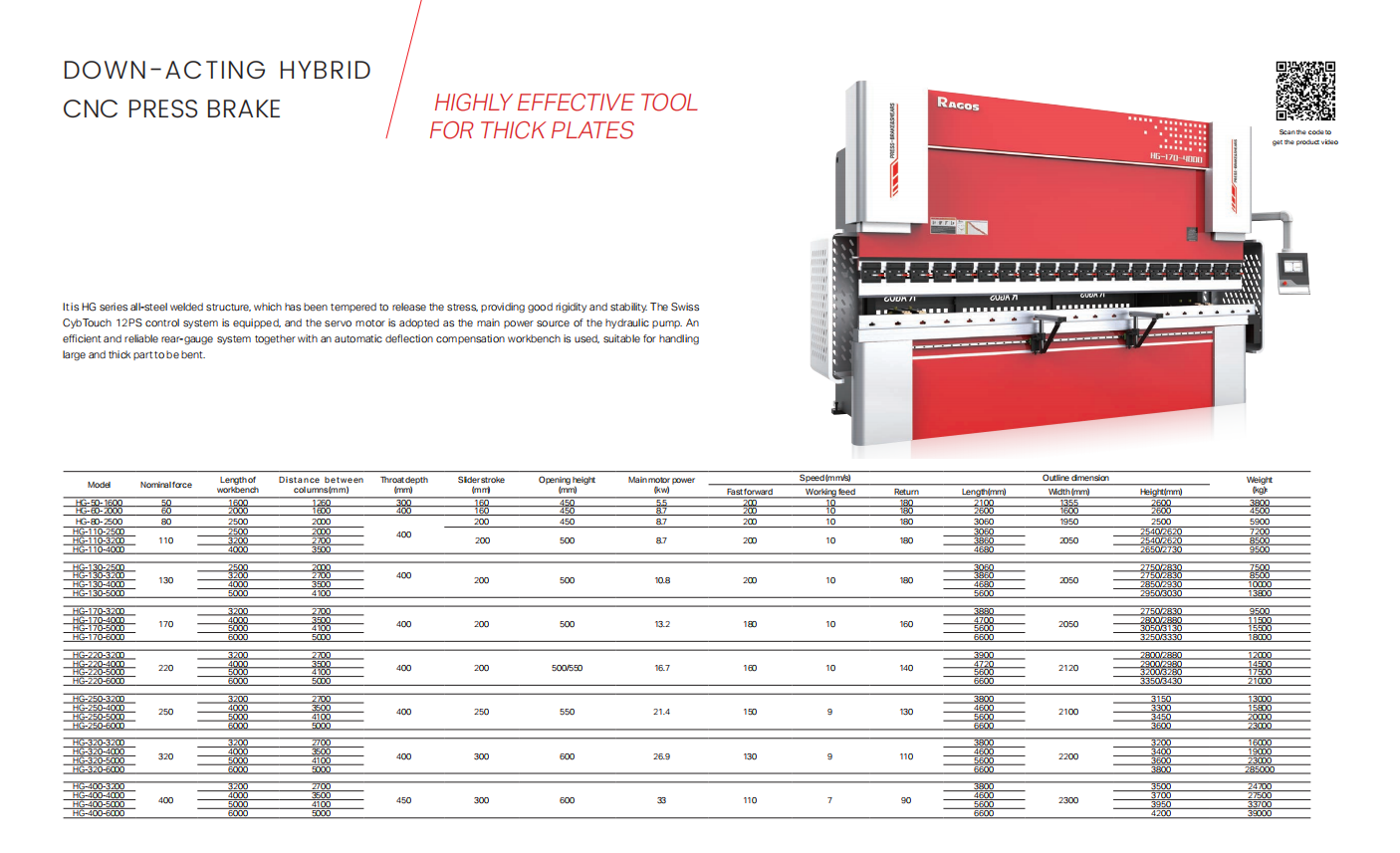

Dual servo hybrid CNC Press Brake

Features:

Down-acting press brake,sheet metal panel benders,cnc panel bender,Automatic Panel Bender,Sheet Metal Bending Center,ragos FOSHAN RAGOS NC EQUIPMENT CO.,LTD. , https://www.ragospressbrake.com

Gauge Feature

Dials Size: 2"(50mm), 2.5"(63mm), 4"(100mm) and 6" (150mm)Case SS304

Pressure range: 0 -100Mpa,other scale units bar, psi, kg/cm2 etc.optional

Ring: Non, black steel or chrome plated

Movement: Brass,SS304 or SS316SocketBrass,SS304 or SS316

Bourdon tube :Phosphor Bronze,SS304 or SS316

Dial plate and pointer : Aluminum

Window Glass or Safety glass

Connection sizes :1/8 for 1.5" case; 1/4 for 2",2.5" case, 3/8"&1/2" for 4",6"case

Connection threads: Metric Thread, NPT, BSP (G, PF), BSPT (ZG, PT)

MountingBottom, back and panel

Accuracy: 2"(50mm), 2.5(63mm)-2.5%Â ,4(100mm) and 6 (150mm)-1.6%

Pressure limitation : 1:Steady: 3/4x full scale value

2: Fluctuation:2/3x full sacle value

3:Short time:full scale value

Product Application

These series of stainless steel gauges are widely used in industries,petrol,chemistry,metallurgy,gas station and pump. Series YTF are designed for harsh and corrosive environments.The filled gauges can reduce the internal gauge damage when the working condition full of vibration and shaking.

*Out door and severe ambient and process conditions.

*Use where harmful vibration and pulsation are present.

*Ideal for hydraulic and pneumatic installation requiring instrument orientation .

*Pumps, compressors, water systems, regulators.

*Suitable for fluid medium which does not clog connection port or corrode copper alloy.

Pressure Gauge Picture

Company Picture

Production Process

If have have interests, please contact with me, i will reply you within 2 hours.

Â

Introduction:

Features And Function

Fast - 10% performance increase by reducing cycle time

High efficiency - 50% increase in energy efficiency (compared to traditional systems)

Precise - positioning accuracy reaches 0.005mm

Features And Function

Fast - 10% performance increase by reducing cycle time

High efficiency - 50% increase in energy efficiency (compared to traditional systems)

Precise - positioning accuracy reaches 0.005mm

Reliable - minimal risk of leakage

Low Noise - Noise reduction in all operating modes

compact - creating new spaces on the midplane

Compatible - easy integration into CNC

Optimization - less installation and service fees

Environmental protection - the amount of hydraulic oil is greatly reduced